Characteristics

- Test type

- resistance, ductility, flaw

- Tested product

- for paint

- Other characteristics

- automatic

Description

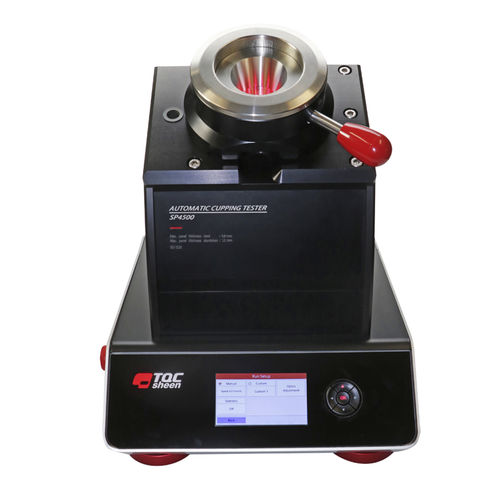

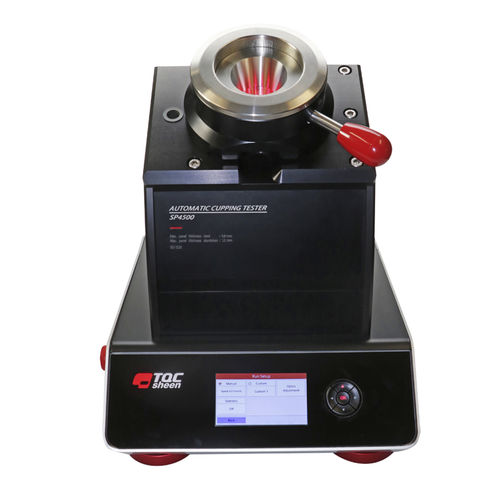

TQC Sheen Automatic cupping tester to perform a cupping (Erichsen / Dent) test on coated steel panels to define the resistance of paint, varnish or related products to cracking and/or detachment from a metal substrate when subjected to gradual deformation by indentation under standard conditions.

The test is either used as a “pass / fail” test by testing to a specified depth or defining the minimum depth at which a coating fails by gradually increasing the indentation.

Constant deformation

The ISO1520 standard requires panels to be slowly deformed at a steady rate between 0,1 mm/s and 0,3 mm/s without interruption. Especially with thicker steel panels hand-operated testers not always allow an uninterrupted deformation. The Automatic cupping tester is driven by a micro-step controlled electro motor which allows precise and steady deformation with 0,01 mm steps. Uniquely this deformation can be paused / resumed.